Armature Service

Service

In my armature service, I offer the following services:

armature balancing

armature balancing and cut commutator

armature service complete:

- clean armature

- polish arm shafts

- dye armature blank

- cut commutator

- armature balancing

shorten armature shafts

grinding armblank outer diameter for perfect roundness or diameter on request

grinding arm shaft to 1,5 mm diameter for smaller pinion

For more information and prices please send me your request by mail to the following address:

Information

|

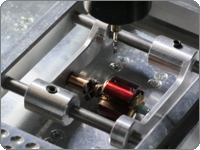

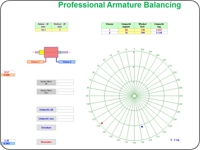

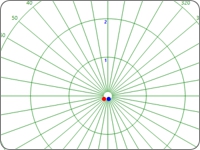

In a computerized precise measurement system, the armature is measured on its balance and transmit back the values to a self created software. |

| Using this software (details on the right) can now be determined exactly where and how much material must be removed so that the balance is at its best. |  |

| After balancing follows the control and a complete remeasurement to check whether the last operation was successful. Here you can see a very good result, which requires no more rework. |

|

For more information and prices please send me your request by mail to the following address:

Basics about balancing

Basics about balancing

|

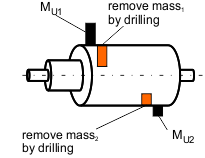

Possible reasons for unbalance - unsymmetrical rotor - unsymmetrical masses due to concentricity errors

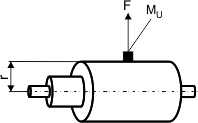

What is unbalance? Static unbalance - can be measured when the rotor is stationary

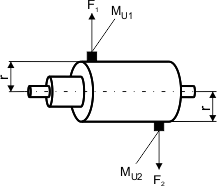

Dynamic unbalance - can only be measured when the rotor is rotating MU1, MU2 = unbalanced masses (in mg)

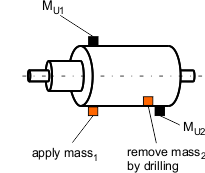

What is balancing? By balancing a rotor, the symmetrical mass distribution is restored. - attaching balancing masses on the opposite side

before balancing: after balancing:

|

Units: |